A packaging solution for a high end die-cast cars

Design Brief

A packaging solution for a high end die-cast cars

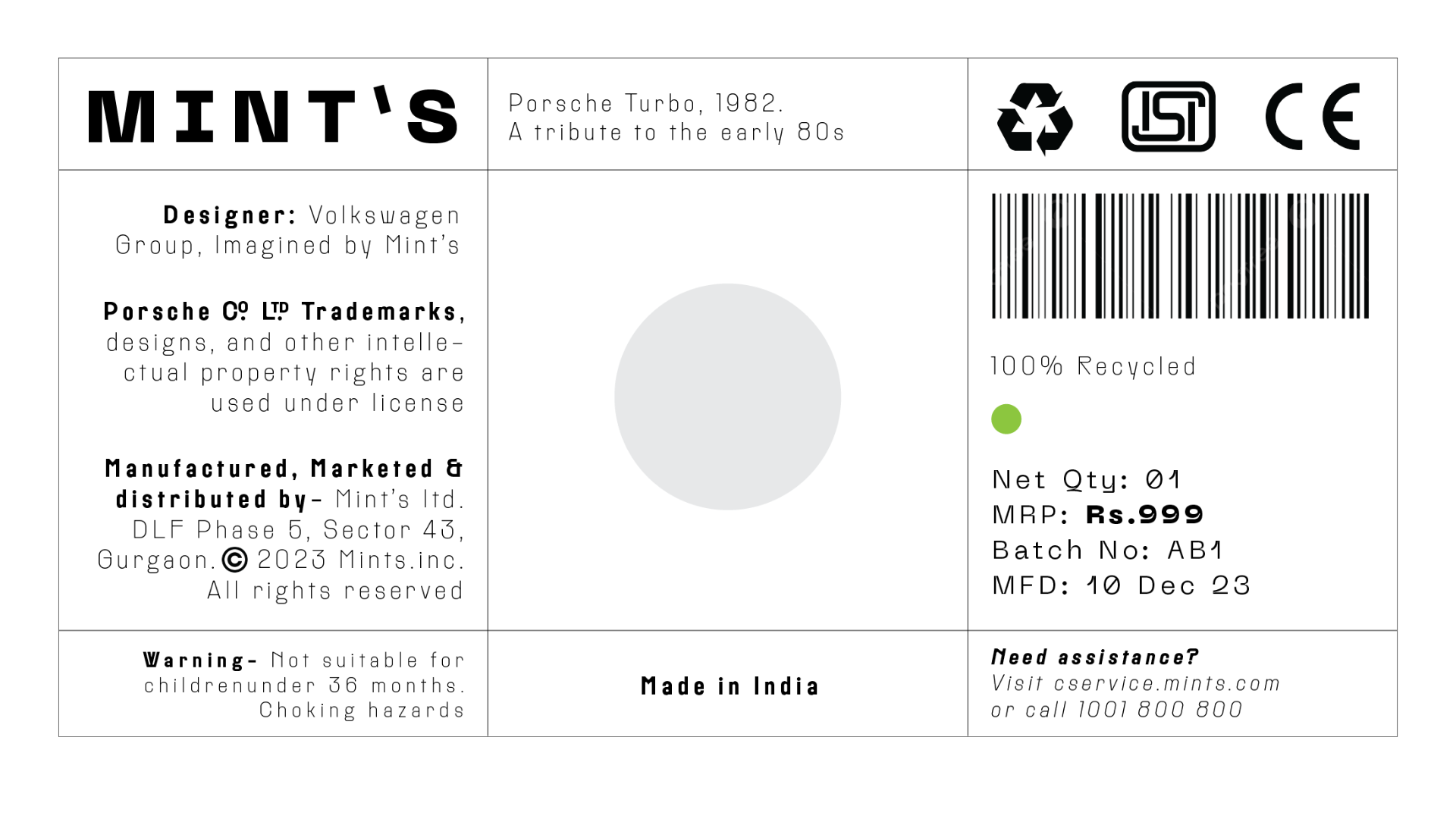

Mint’s is a die cast car brand that emphasizes on premium aesthetics, utilizing environmentally friendly materials for the packaging, and building a distinct brand identity centered around these principles. The brand seeks to compete with existing die-cast car manufacturers by combining high-quality products with a strong commitment to sustainability.

Our mission is to blend top-notch quality with unwavering sustainability, setting us apart in the world of die-cast car manufacturing.

Our Story

We kickstart our venture as an eco-friendly brand, dedicated to merging sustainability and aesthetics seamlessly. The focus begins with environmentally-friendly packaging and extends to crafting and designing mint-y diecast cars from recycled materials. These designs harmonize with carefully sourced, processed materials from around the world, offering a unique and conscious experience.

The idea is to be a new age brand taking on the likes of hot wheels and majorette, while also bringing a fresh new approach to this industry. Mint’s idea is to bring sustainability to the market of diecast cars, but with a twist towards its packaging that can act like a showcase.

Materials-

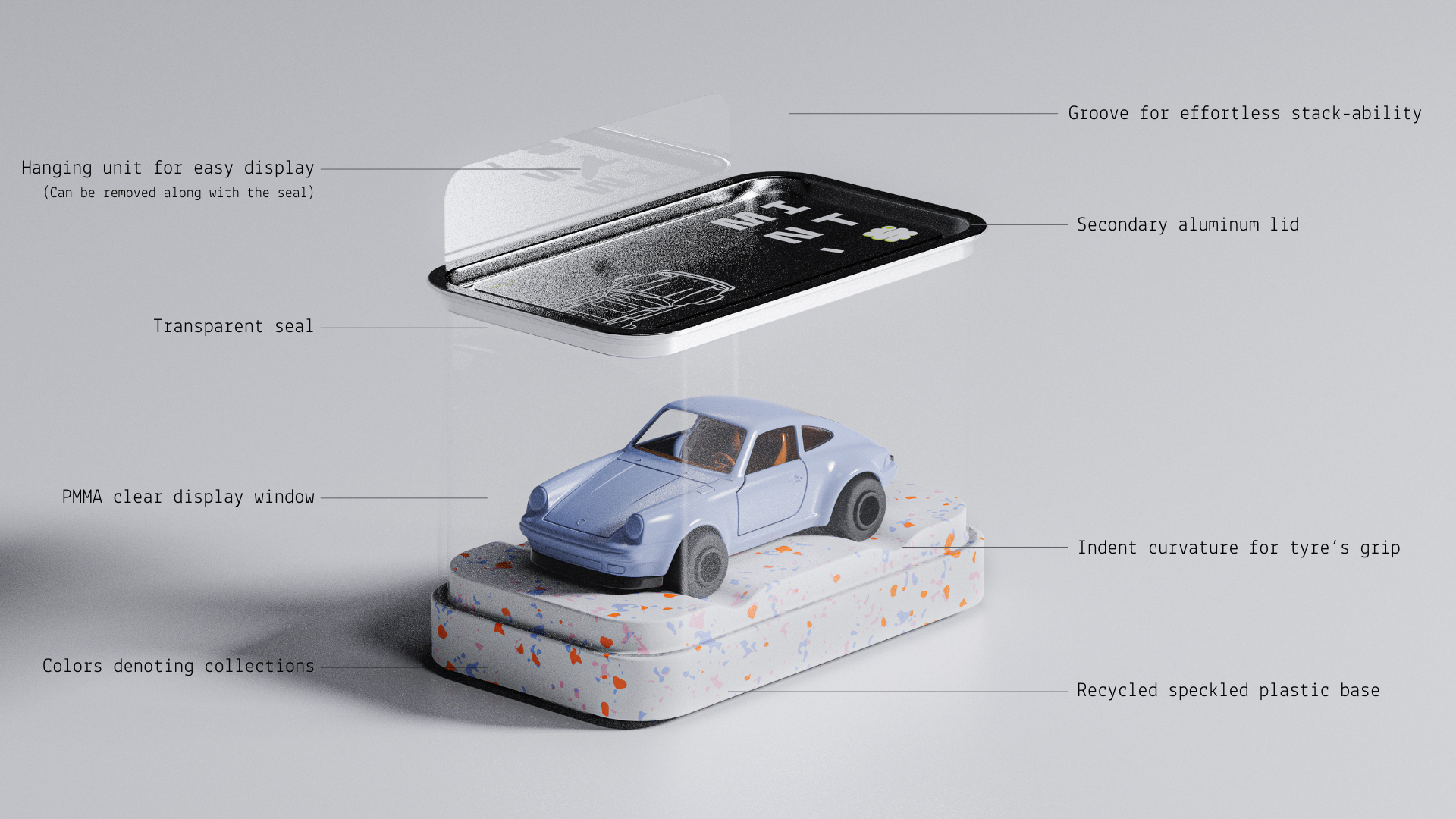

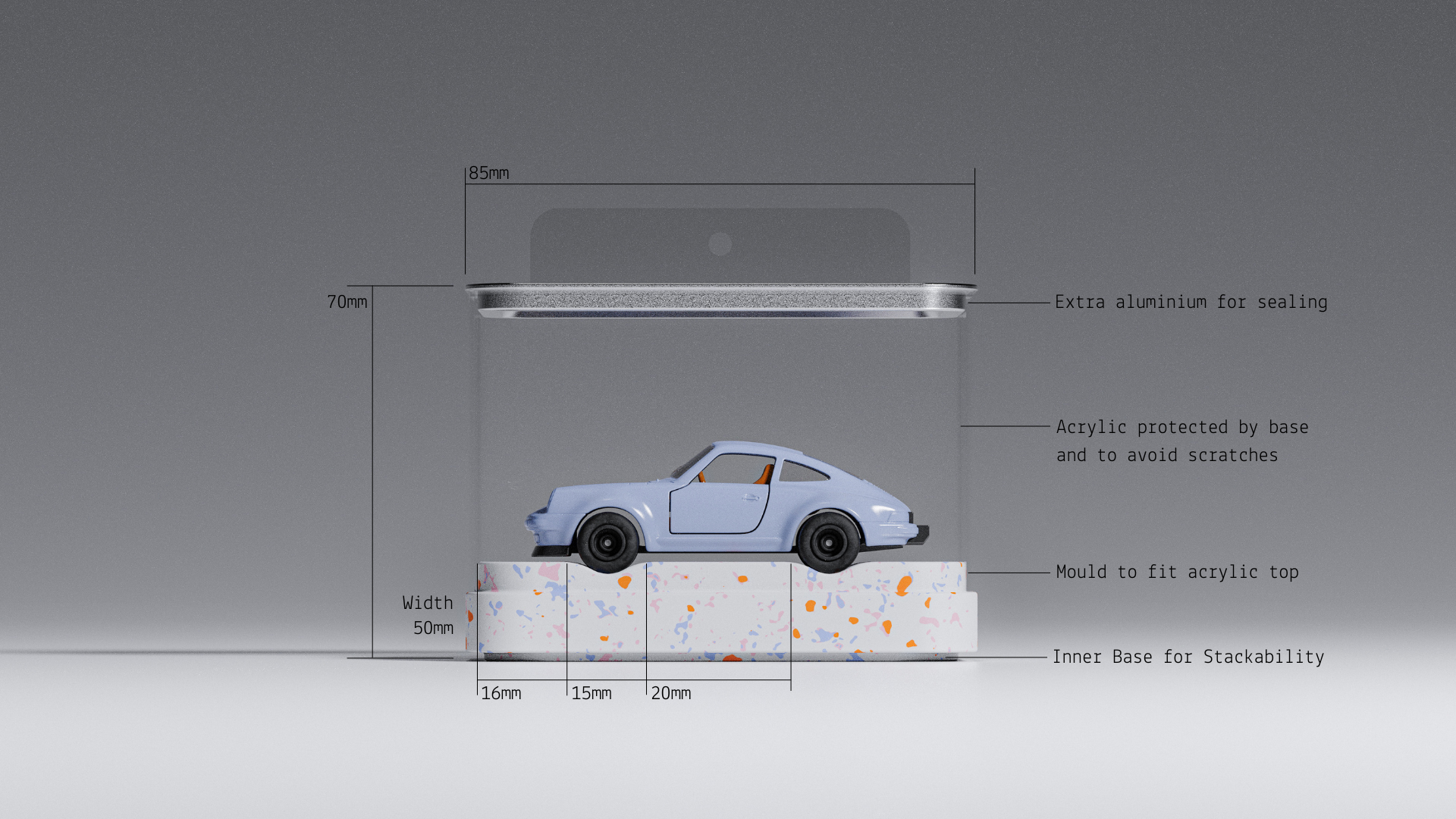

(100% recycled)Secondary Aluminum(Recycled), Recycled acrylic(PMMA) and Recycled speckled plastic

1. Secondary Aluminum(also called Recycled Aluminum)The lid of the packaging is made of of aluminum that is made from recycling cold drink cans.

Aluminum is the most recyclable industrial material, aluminum can be recycled infinitely to produce the same product. Recycling aluminum also saves 95% of the energy used in its production from raw materials. Since, 85% of aluminum is recycled in India, it is easier for the brand to include it in the production.

In MINT’S manufacturing process, the aluminum will be powder coated to make it highly resistant to wear and tear, corrosion, fading, and chipping.

Printing process- Dye Sublimation(a process of printing on special paper and then transferring the photo to an aluminum surface using a heat roller) will be used to print our graphics onto the lid as unlike the traditional method of printing directly on the surface, which may damage easily, dye sublimation infuses the image directly into the hard coating to provide lasting durability and protection.

Price-Rs. 170/kg

2. PMMA sheet(Recycled acrylic sheet)

The clear window in the packaging is made up of Polymethylmethacrylate (PMMA) sheet which is basically recycled acrylic sheet.

Polymethylmethacrylate (PMMA) is a thermoplastic polymer, also known as acrylic or acrylic glass is a transparent and rigid thermoplastic often used in sheet form as a lightweight or shatter-resistant alternative to glass. It is made by the process of depolymerization and 100% recyclable.

PMMA is inherently stable to UV-light, PMMA is used for many outdoor applications, in which it maintains its original color and finishes for many years. PMMA also has excellent scratch resistance and is able to be processed to a very high gloss finish.

Price- Rs. 80/kg

3. Speckled Plastic(Recycled Plastic)

The base of the packaging will be made up of recycled plastic sheets that comes from old bottle caps and bottles.

This type of plastic is achieved by melting and solidifying tiny pieces of plastic together. It is designed to express a limitless range of textures that would reflect a spectrum of consumer tastes and sensibilities while taking into consideration global companies who are seeking more refined exterior material, sophisticated design of craft, cost-savings in mass production and faster production speed.